Function:

Uses hot air circulation and wind cone type, and conducts drying curves at the requirements of technology to dry wet billet for honeycomb catalyst.

Brief introduction to working conditions:

1.Drying system

1.1

This catalyst products requires slow drying according to the drying curve with a certain humidity and temperature in the process of drying. With the continuously heated, water gradually evaporates and discharges, and the humidity of kiln is controlled variables over time. Adopting temperature and humidity test and the closed loop control.

1.2

Using steam air or electric heating, and controling circulating air humidity to satisfy the requirments of drying curve.

1.3

The dry air adopts centrifugal ventilator extracting indoor humidity after heating evenly transfer into the drying chamber, and for recycling. There are many holes on the wine cone, and setting tuyere baffle to meet the requirement that the temperature and humidity is uniformity. Moisture vent and spray humidification system are setted on the external pipeline, the testing point would return the feedback signal to PLC and adjust air temperature and humidity automatically to achieve the conditions for products needed.

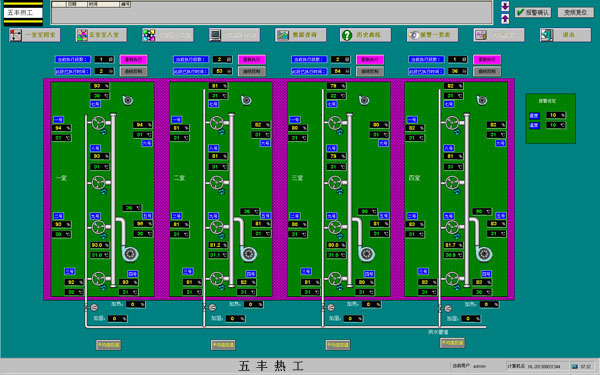

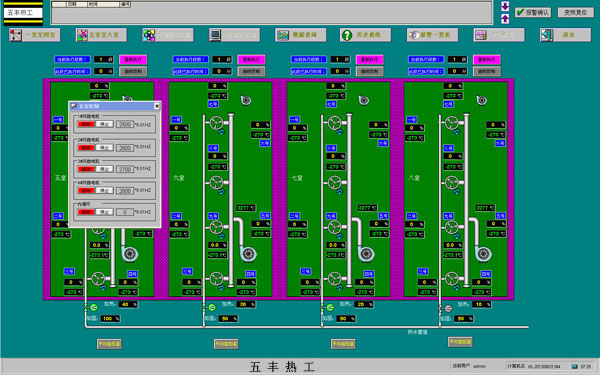

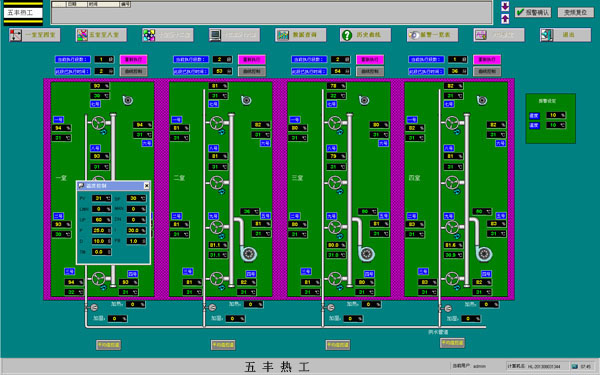

2.Control system

The control system of drying chamber mainly includes the temperature, humidity, hot air circulation. Control system adopts IPC and PLC, realize the control of equipment independently, Includeing power control, temperature control, pressure control, safety control and so on.

2.1

Temperature control could control hot air temperature through themal resistance adopts signal of the exchanger outlet air temperature and electric heater power controls heat exchanger. Heating products in the drying chamber, through the industrial computer control system, temperature and humidity detection device and electric heat exchanger to realize the objective that control temperature and products temperature are same. The control system could set heating curve to make the products heating and drying in accordance with the heating rate.

2.2

Humidity control accepts the signal through humidity sensor adopts air humidity in dry chamber, then transfer into computer control system and comparing with the humidity curve. While the output signal would control the opening of humidity device and regulate the quatity of water in hot air pipe. When the indoor humidity is too large, then stop the spray humidification, open the wet door to circulation. Through closed-loop adjusts indoor humidity to reach the requirement of the setted curve. When indoor humidity is too small, close the wet valve, open the spray humidification. Through closed-loop adjusts indoor humidity to reach the requirement of the setted curve.

2.3

Hot air circulation control makes products to be heated evenly through circulation fan extracts air in the dry chamber, after mixing with hot air in the pipeline, it needs heat then flow into chamber.

Effect:

After finishing first grade drying, the water content of catalyst should control within 12 to 26 percent.

.jpg)

Home| About us| Catalogue| Honor| Project| contact us

Copyright © 2000-2015 www.sinodafeng.com ShiJiazhuang Dafeng Furnace Co., Ltd.